-

-

-

-

-

Ugent Tech in the Spotlight

Explore our achievements and innovations led by founder Mr. Tom Khoo Hai Hing.

Learn More -

Ugent Tech Blog

Stay updated with the latest insights, news, and innovations in graphene and advanced materials.

Read More

Our products

- Graphene

- Multi-walled Carbon Nanotubes

1

/

4

- Graphene and CNT Ink and Paste

- Anti-Static Ink

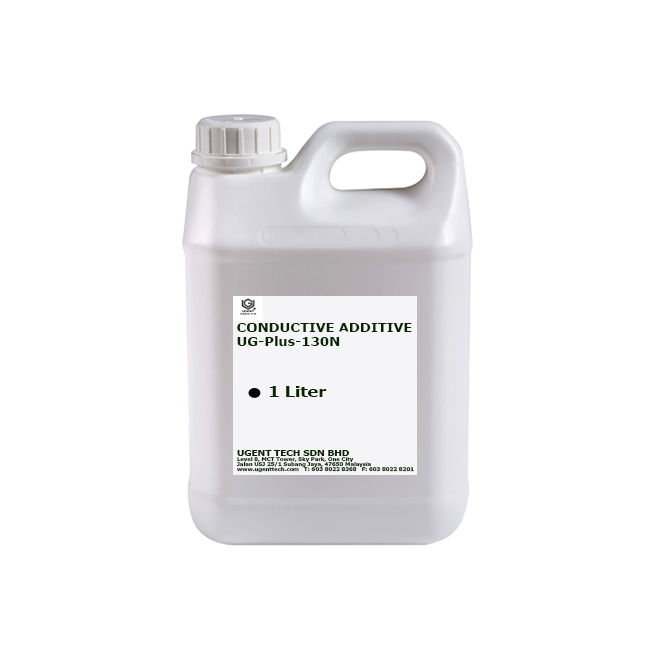

- Conductive Additive - Li Battery

- Drilling Fluids Additive

- Heat Transfer Fluid

- Advanced Sanitization & Odor-Neutralizing Solutions

1

/

6

1

/

accessibility.of

3

Frequently Purchase with

1

/

4

All Products

View all

1

/

8

Blog post

Learn More-

Mr. Khoo Hai Hing, Founder, Ugent Tech Sdn Bhd

The Science Behind Heat Transfer Fluids: Keeping Cool in a Fast-Paced Digital World

Heat transfer fluids Thermal management Cooling systems Graphene-based solutions Computer cooling Gaming system cooling Electric vehicle cooling Industrial equipment efficiency Battery performance Digital cooling solutions Malaysia heat transferRead more -

Mr. Khoo Hai Hing, Founder, Ugent Tech Sdn Bhd

How Graphene is Transforming Energy Storage and Batteries

Discover how graphene is revolutionizing energy storage and batteries. Learn about its impact on lithium-ion batteries, supercapacitors, and renewable energy solutions at Ugent Tech.Read more -

Mr. Khoo Hai Hing, Founder, Ugent Tech Sdn Bhd

What is Graphene and Why is It the Material of the Future?

Learn about graphene, the game-changing material with incredible strength, conductivity, and flexibility. Discover its applications and how Ugent Tech is leading innovation in graphene production...Read more -

Mr. Khoo Hai Hing, Founder, Ugent Tech Sdn Bhd

The Revolutionary Impact of Graphene in Modern Technology and Industry

Discover how graphene is transforming industries with its strength, conductivity, and versatility. Learn its applications in electronics, energy storage, aerospace, and more in this guide...Read more

1

/

accessibility.of

4